In its facilities Patros combines several skills, which are:

– rapid prototipation;

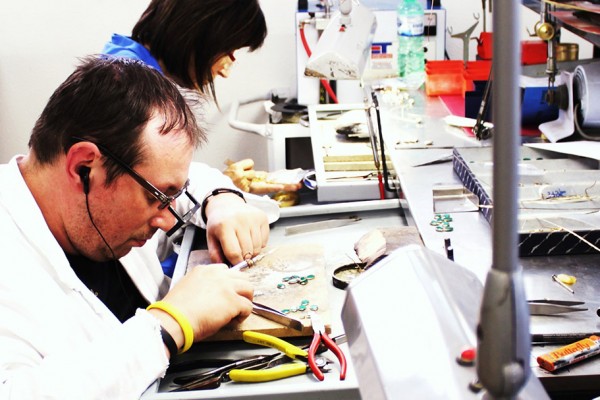

– setting by microscope;

– hand-engrave by “Bulino”;

– designing and programming by 3D programs;

– lost wax casting;

– stamping;

– die-casting;

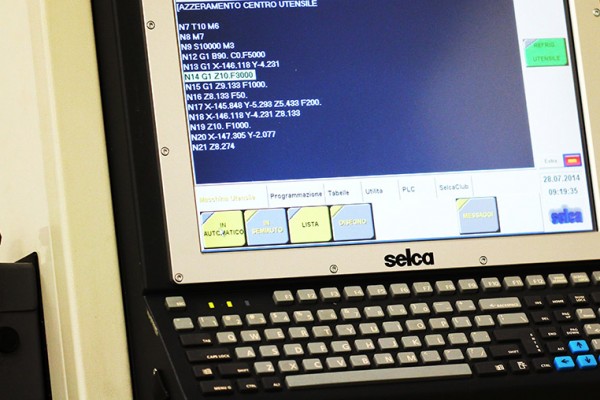

– CNC turning (from 3-axes to 11-axis machines);

– CNC milling (three-axis and five-axis continuous machines);

– laser cutting, writing and welding;

– sintering bio-ceramics;

– flexibility, by making both precious (gold, silver and platinum) and non-precious materials (brass, bronze, Stainless Steel, titanium, ecc.).

Moreover, Patros has started a enhancing strategic project in social and environmental responbility, getting important certifications like the Responsible Jewellery Council COC and COP.